Why another one?There are so many already!

Well, I’ve printed over a kilo of other tracks and whilst they all work great, every time I played with them with the children, the perfectionist in me could only focus on the small design details.

So with my experience as an engineer in the train building video game Factorio, I got down to business.

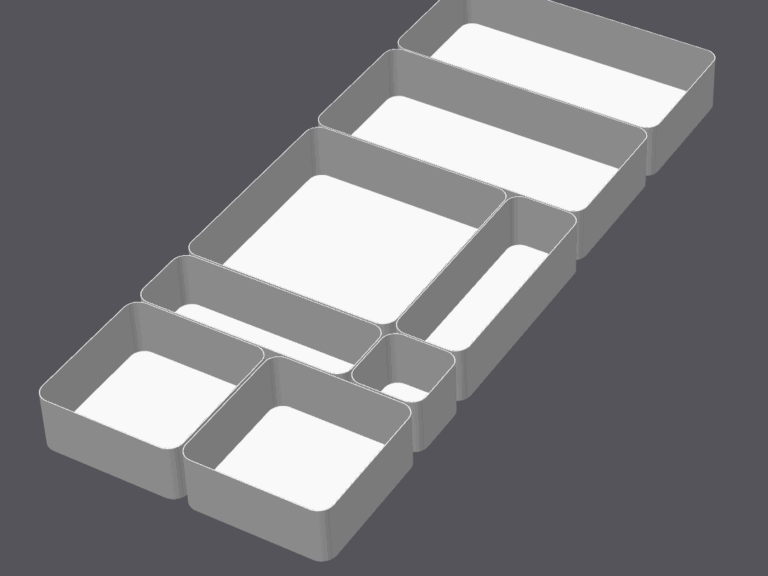

Here are the small design details I’m now happy with:No small connectors: no choking hazards and faster track buildingThe curved tracks have correct proportions to connect with the straight tracksThe non-symmetric tracks are double sided and designed for clean printing with multi-material supports, and with print profiles with supports optimised for satisfying removal (check out the demonstration videos below): this makes the tracks are watertight and much easier to clean!They fit together tighter (but still easy),They don’t have fillets on the bottom edges or in the grooves making them print cleaner and look neater when printed,And finally, they are modelled from scratch and exported in high quality for clean geometry with no mesh artifacts and with smooth curved surfaces.As someone with young kids, I use them regularly and will be making additions for years to come (I’ll share them of course)!Compatibility and extensionsIn the design of these tracks, there was a big trade-off between making them widely compatible and making two printed tracks fit well with each other. because the tracks from the two biggest brands – Brio and Ikea – don’t fit well with each other, maximising compatibility would mean making the lugs small and the slots big so that they will technically “fit” and you can call them “compatible with all systems” but would also mean that the fit is always very loose, even between two printed pieces.

As many users, once they start printing their own tracks, will eventually replace all of your wooden tracks (as the printed ones just work better and have more variety of tracks), or don’t have any wooden tracks to begin with, I decided to go for a snug fit (and thus fewer train derailments) over universal compatibility. Each print profile has a small test piece on the first plate so you can test the fit with your existing wooden track set. So far, users have reported:@frederik_a: Nice fit with BrioIkea Lillabo – see belowGeneric white-label train sets available at many toy stores that appear to be made at the same factory – good fit (see below)“Chad Valley” in the UK“Busy Town” in New Zealand, etc.Lidl Playtive – TBDHolzeisenbahn – TBDEichhorn – see belowTracks from a generic white-label train set fit well on these tracks.Trains from a generic white-label train set run well on these tracks.Ikea Lillabo tracks fit tight on one side and fits slightly loose (all wooden tracks tend to fit slightly loose with each other) on the other side.

The tracks align well and the trains can still go between them easily.Ikea Lillabo trains including the motorised one runs well on these tracks.Deutsche Bahn (DB) trains you get with a child’s ticket on the ICE also run well here.Thanks to @uphax for these photos!To better link Ikea and Eichhorn tracks (which have slightly shorter lugs) to the printed tracks, an adapter piece is available: If you want to create your own tracks that fit well with these, please have a look at the STP files for the basic dimensions.

Note that all tracks are 0.2mm shorter than their nominal length – this is because there is 0.1mm setback on each end providing a nominal clearance of 0.20mm between ends of tracks.

All other clearances are 0.25mm to give the tracks some flexibility.

Please see the drawing below.Supports for non-symmetric tracksThe included profiles have supports optimised for surface finish and support removal.

PETG support interface layer is needed for PLA tracks and PLA support interface layer is needed for PETG tracks.

AMS or AMS lite required.Surface finish comparisonSupport interface layers (PETG for PLA, PLA for PETG)And here is a support removal demonstration: You can read more about this methodology on the Bambu Lab Wiki.No-AMS Multi-Material Reusable SupportsIf you don’t have an AMS or equivalent, having issues with nozzle cross-contamination or you just want less waste, you can print PETG supports before-hand and add them into the PLA track print with a pause!

The pause can be pre-programmed in the slicer so you don’t need to wait there for the perfect moment.

Pause has been incorporated in the included “Reusable Supports” profile – test it out with the first two plates! In this example, I am using Bambu Lab PETG HF and Bambu Lab PLA Matte.

The grey PETG supports were printed first.

Then the blue PLA part printed until the pre-programmed pause.

I lowered the bed manually (mainly for the photo) and inserted the grey PETG supports.After you insert the supports, press resume and the printer will continue printing over them:This method will produce much better results than just regular bridging (printing over air).